The St. Croix Coastal Zone Management Committee on Tuesday tabled a request by Diageo USVI for modification of its major CZM permit, CZM-10-09L, to allow the company to construct a “lined evaporation pond,” after attorney Kevin Rames, representing Lockheed Martin, expressed concerns about the modifications.

At the meeting, Trinity Austrie and Benjamin Keularts from Tysam Tech, an environmental firm representing Diageo, said the 10-acre lined evaporation pond will serve as a key component of the existing wash water treatment system. The pond will be used to responsibly manage any treated bio-condensate that is not re-used at the facility and a continuous small stream of wastewater resulting from the site’s reverse osmosis systems and unit blowdowns, they said.

Rames said that Lockheed Martin’s main concern is to “ensure that throughout the entire process that the interest of Lockheed Martin is understood, acknowledged by Diageo and protected by both Diageo and the CZM Committee.”

Rames said Lockheed Martin has been engaged in a remediation effort at the St. Croix Renaissance Group LLC property, and that remediation is under the jurisdiction of the United States District Court for the district of St. Croix and was put into place because of a lawsuit that was filed by the Department of Planning and Natural Resources against Lockheed Martin and others, which he has defended.

The Harvey Aluminum Corp. began developing the first plant on the site in 1962 and several different companies owned the manufacturing plant over the ensuing 40 years, the last being St. Croix Alumina. Over the decades, the plant produced millions of tons of caustic bauxite tailings as a byproduct of making aluminum. Lockheed Martin has been handling the remediation efforts of what is known as the “red dust.”

“Lockheed Martin takes remediation efforts very seriously. Anything that appears to have an impact on the remediation efforts is something that they will pay close attention to,” said Rames.

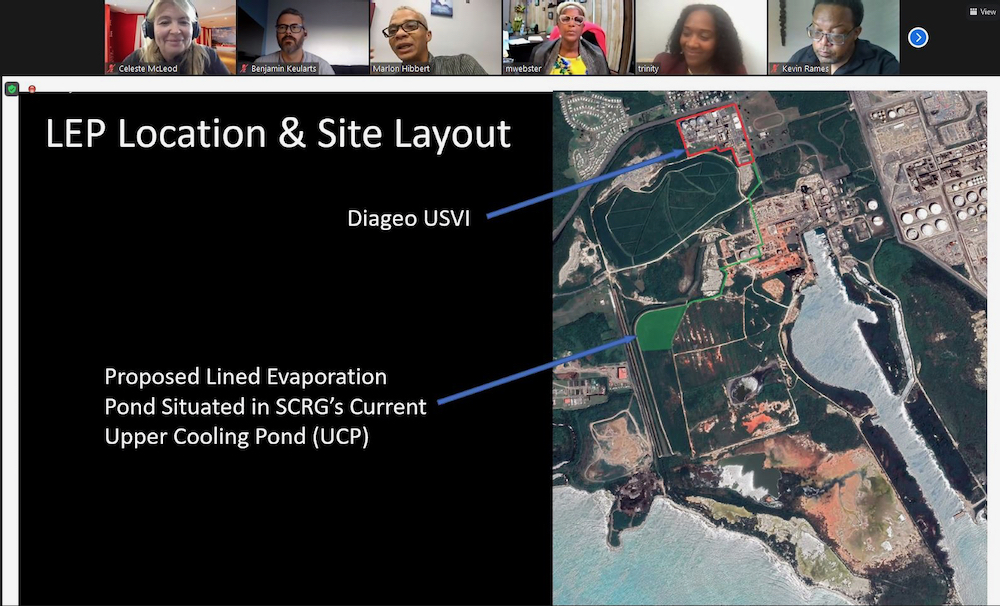

Diageo said that if approved the pond will be located at the existing upper cooling pond on the St. Croix Renaissance Group, LLLP property at No. 1 Estate Anguilla, in the south shore industrial area. Currently, the area of Lockheed Martin’s concern is a six-foot separation between the berm in what is referenced as “Area B” and the berm to be constructed by Diageo. What Lockheed Martin is requesting is a 10-foot separation between the berm for Lockheed Martin and the evaporation pond. The request for additional space is so that Lockheed Martin can move heavy equipment in its remediation efforts.

“We want to be assured that Lockheed Martin is informed of the development final design of the evaporation pond,” said Rames. “We recognize what you need to do needs to be protected, and you need to recognize that what we need to do needs to be protected. I would urge Tysam Tech to engage more fully, more openly and more comprehensively.”

Rames assured the committee that Lockheed Martin has no interest in the business relationship between St. Croix Renaissance Group, LLLP and Diageo. Tysam Tech also confirmed that prior to presenting to the committee they had gained permission from their landlord, St. Croix Renaissance Group, LLLP.

Other aspects of the design for the lined evaporated pond include mechanical sprayer units developed with consideration for potential maximum drift from the spraying process to ensure overspray of material will land within the boundary of the pond, Keularts said.

To minimize the hydraulic retention time that would be required for evaporation, 18 mechanical sprayers will be installed to enhance the evaporative process. The sprayer design chosen is the SMI Model 420F sprayer that disperses the aerated liquid up to 25 feet in the air, and drift in worst-case conditions would be approximately 400 feet.

The sprayer layout, positioning and volume will allow drift control even during heavy winds. The pond design allows for the containment of a 1,000-year storm as well as an additional freeboard of three feet. The liquid depth of Diageo’s process water is limited to no more than 4.6 feet. The system does not require water and can operate on a continuous basis to control odors from the pond.

“The maximum flow rate to be discharged to the pond will be 210 gallons per minute,” said Austrie. The total evaporation system manages as much as 230 gallons per minute without increasing the depth of the liquid level in the pond.

After a 30-minute executive session, the committee members decided to further discuss what was presented before moving forward.

Committee members present were Chairwoman Masserae Sprave-Webster, Kai Nielsen, and Carl Simmonds.